Discover the Creativity of In-Mold Decorations in Production

Discover the Creativity of In-Mold Decorations in Production

Blog Article

Grasping In-Mold Decorations: Techniques, Fads, and Finest Practices for Optimum Results

In the world of manufacturing, the art of in-mold designs stands as an essential facet of product layout and production. As sectors consistently seek cutting-edge methods to boost visual charm and capability, understanding the complexities of in-mold decors has become a critical ability. From selecting the ideal products to incorporating innovative design trends, the trip in the direction of achieving optimal outcomes in this domain name is multifaceted. By delving into the strategies, patterns, and ideal practices that underpin successful in-mold design procedures, organizations can open a world of opportunities that not only elevate the aesthetic appeal of their items yet also improve production effectiveness and strengthen customer engagement.

Product Option

Product option is an essential aspect of grasping in-mold decorations, as it directly influences the top quality and longevity of the end product. When choosing materials for in-mold decors, it is vital to consider factors such as compatibility with the molding process, the preferred aesthetic outcome, and the environmental problems the item will deal with. Polycarbonate materials like polypropylene, abdominal, and polycarbonate are frequently used for in-mold decors due to their flexibility and ability to attain elaborate designs. These products provide excellent moldability, enabling suppliers to produce intricate shapes and patterns with precision.

Furthermore, products with high warm resistance are liked for in-mold decors, specifically for items that will certainly be exposed to elevated temperatures during their lifecycle. By thoroughly selecting the suitable material for in-mold designs, suppliers can boost the total high quality and toughness of their items, satisfying the assumptions of both end-users and customers - In-Mold Decorations.

Layout Advancement

A crucial variable in progressing the area of in-mold decors is the continual expedition and application of style development techniques. Layout technology plays a vital duty in boosting the visual charm, functionality, and overall top quality of items produced using in-mold decor procedures. By integrating cutting-edge style aspects, manufacturers can separate their products in the market, bring in consumers, and stay in advance of competitors.

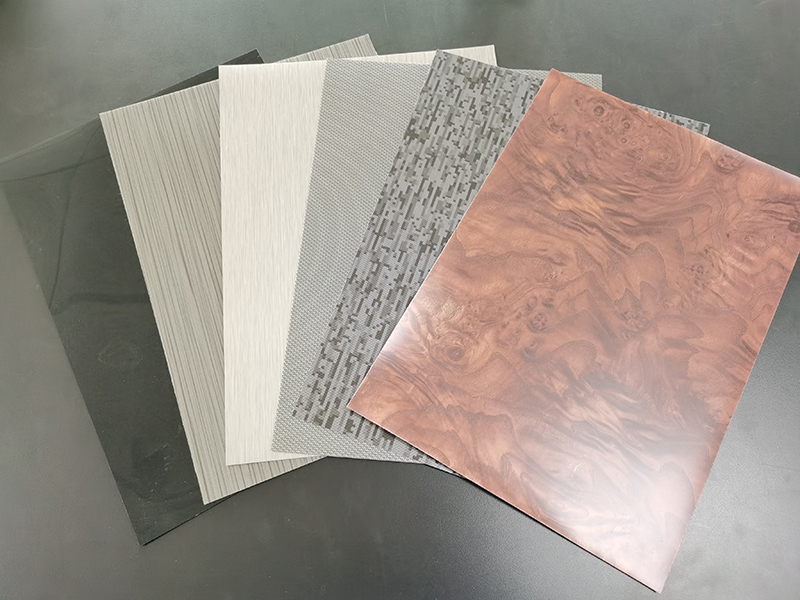

One of the crucial elements of layout innovation in in-mold designs is the integration of detailed patterns, structures, and graphics that were formerly challenging to achieve with standard design methods. Advanced modern technologies such as 3D printing and digital layout tools make it possible for designers to produce complex and thorough styles that can be flawlessly transferred onto shaped parts. Furthermore, making use of lively colors, metallic coatings, and special impacts like gloss or matte structures can even more elevate the visual charm of in-mold decorated products.

In addition, layout advancement extends past visual appeals to incorporate functional enhancements such as ergonomic forms, integrated features, and adjustable components that satisfy particular customer demands. By welcoming style advancement, manufacturers can unlock new opportunities for personalization, product, and creative thinking differentiation in the competitive landscape of in-mold designs.

Manufacturing Performance

Efficient production procedures are vital for equating the innovative designs created in the field of in-mold decorations right into top quality completed products that fulfill market demands and consumer assumptions. In the realm of in-mold decors, manufacturing effectiveness encompasses numerous essential aspects that add to the total success of the production procedure.

Automation not just speeds up the manufacturing procedure yet likewise boosts precision and repeatability, leading to a more uniform and top notch end product. Generally, a holistic strategy to production effectiveness is paramount in optimizing the potential of in-mold decoration strategies and accomplishing optimum outcomes in the affordable market landscape.

High Quality Control Procedures

What are the essential methods for guaranteeing stringent top quality control procedures in the realm of in-mold decorations? Quality assurance steps are critical in in-mold decoration processes to make sure the production of top quality and perfect completed products. One crucial strategy is the execution of rigorous inspection protocols at every phase of the production procedure. This involves performing complete aesthetic assessments, dimensional checks, and color uniformity evaluations to recognize any variances or issues early on.

Making use of innovative technologies such as computerized inspection systems can additionally boost the top quality control procedure by offering trusted and accurate data for analysis. These systems can find flaws that may be missed out on by hands-on examinations, thus improving general item top quality and consistency.

Normal here training and growth programs for employees associated with the in-mold design procedure can likewise add to preserving top notch standards. By enlightening personnel on best methods, quality assumptions, and the significance of focus to information, companies can promote a society of quality consciousness throughout the organization.

Consumer Charm

To boost the bankability of in-mold decor products, catering and recognizing to consumer choices play a crucial role in identifying their charm and success. Customer appeal in in-mold designs is influenced by various variables, consisting of design aesthetic appeals, color selections, durability, and overall capability. Customers are significantly seeking individualized and distinct products that reflect their originality and style. Using customization alternatives such as customized styles, shade variants, and textural elements can dramatically boost the Web Site allure of in-mold decor items.

Conclusion

In-mold decors use a efficient and versatile means to boost product aesthetic appeals. Understanding in-mold decorations needs a holistic strategy that takes into consideration all elements of the manufacturing procedure to guarantee success.

In the world of manufacturing, the art of in-mold decors stands as an essential element of item style and production. Layout advancement plays a crucial role in boosting the aesthetic appeal, capability, and overall top quality of products manufactured making use of in-mold decoration procedures.One of the essential facets of style innovation in in-mold designs is the integration of intricate patterns, appearances, and graphics that were previously testing to achieve with typical decoration approaches.Efficient manufacturing processes are crucial for translating the cutting-edge designs established in the area of in-mold decorations right into high-grade completed items that meet market demands and customer assumptions. Providing modification options such as individualized layouts, color variations, and textural components can significantly improve the charm of in-mold decor products.

Report this page